Grabbed a machine I’ve been keeping an eye on for a while this weekend. It’s been advertised for several weeks and just hit the magic $300 mark so I gave the seller a call and picked it up this past Sunday.

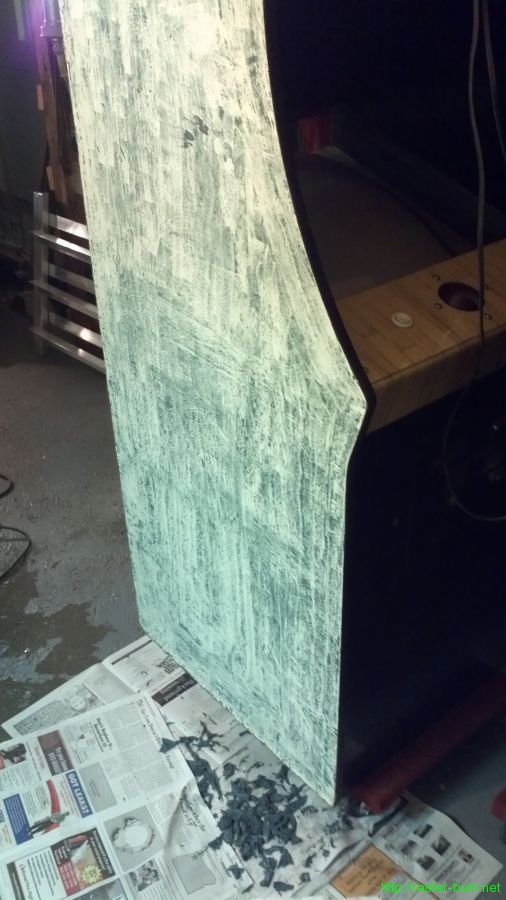

Bosconian, released under license from Namco by Midway in 1981, is pretty rare to find in its dedicated form anymore. Lots and lots of them were converted, and the cabinets are made out of some particle board that doesn’t hold up well at all compared to the plywood cabinets used for other Midway games.

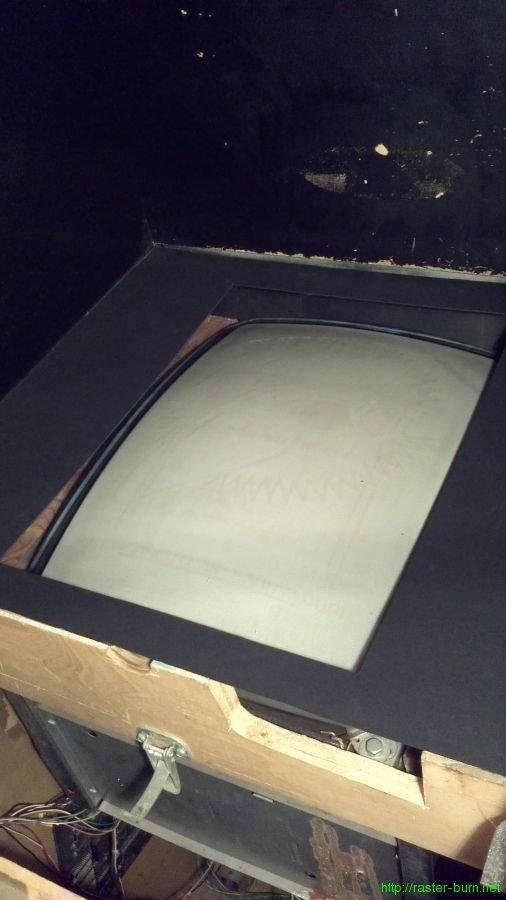

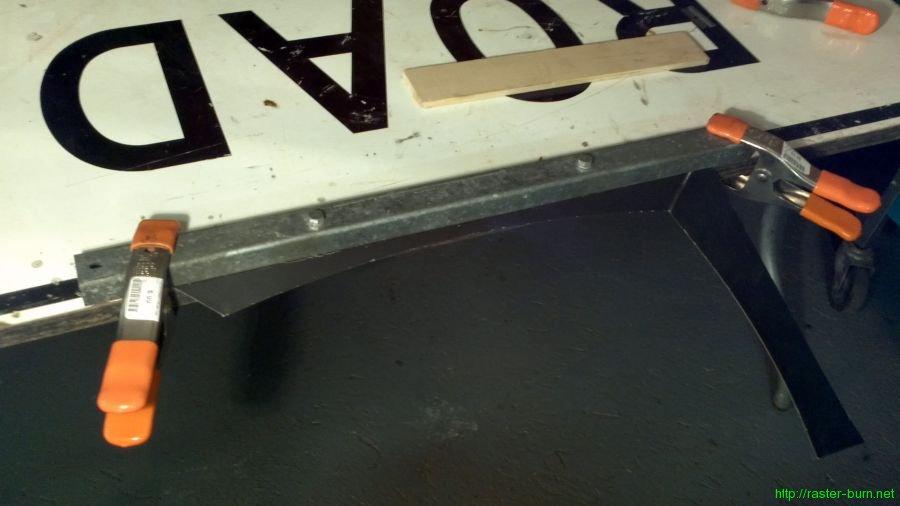

This one is only the second or third I’ve ever seen in person. It’s in decent original condition, with plenty of signs of having been on route but no gratuitous damage for the most part. Only things I might repair cosmetically are the plastic strip at the bottom of the front panel that has come loose, and perhaps replace the control panel overlay that has worn badly on the front edge.

It definitely needs a bit of electronics attention. The audio doesn’t work currently, which hopefully is just a common issue with the amplifier. I’ve also noticed the mini map dot for the player’s ship will often end up drawn on the opposite side of the screen from where it belongs, which makes the game a little harder. Going to leave it as is for a while before I dive into troubleshooting though.

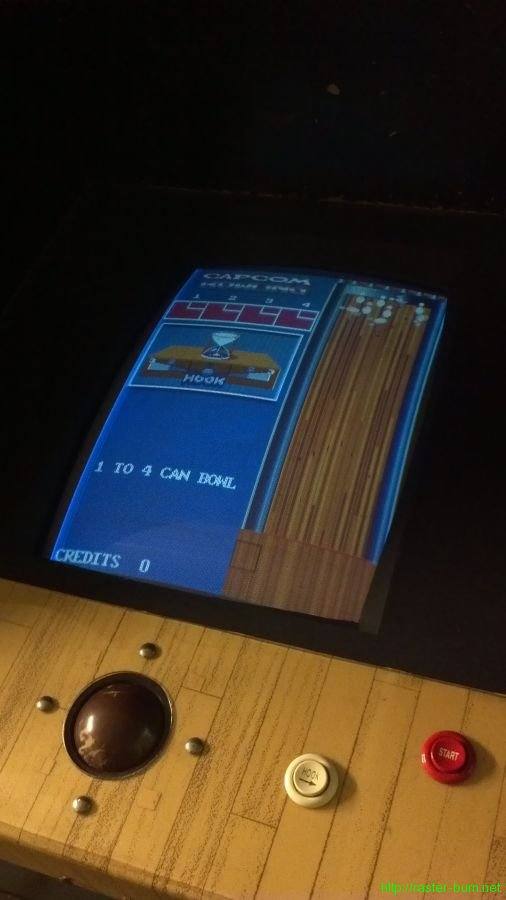

The Bosconian went straight to my workplace’s new offices in downtown Portland, joining the rest of the lineup that was moved over the week prior. I also hauled over the former-Bosconian I have, a Capcom Bowling conversion.

There’s still room for more on the opposite wall, but I haven’t totally decided what else to bring in. Will give things a few more weeks to settle out before I add on further.